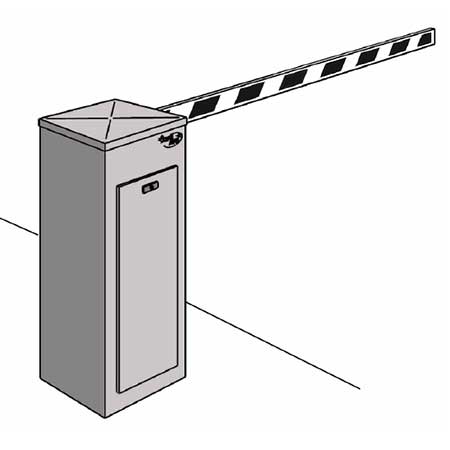

High-speed automatic rising barrier especially designed for access control in public and private parking lots as well as industrial sites. The Flex-18 barrier has been developed to ensure an economical vehicle access control for lanes up to 20 feet, while providing dependable efficient control and safe every day use.

Demonstration Video

Technical Characteristics

- Shaft output left or right, to be specified with order.

- Standard power supply 120V AC single phase ( ±8%).

- Frequency 50-60HZ.

- Reversing Motor 1/3 HP – 1625 RPM.

- Operating time 2 -4 seconds depending on arm length.

- Worm screw type life lubricated gearbox.

- Compression springs available in 1 to 3 spring configurations depending on arm length.

- Programmable logic controller with LCD display, allows for uploading of logic changes.

- Run timer, safety edge timer, auto close timer (jumper enabled).

- Operating Temp. –35° to +70° C.(-31° to 150°F)

- Net weight from 90 to 96 Kg (200-215Lbs), (arm included) depending on arm length.

Available Options

- Wooden gate arm up to 12 feet or Aluminum arms up to 20 feet.

- Push button controller, RF receiver, extrasensory or contact safety edge, internal access controller.

- Vehicle presence detector (three slots available).

- 10 IO controller for use in access control applications.

- 26 IO controller for use in revenue control applications.

Important Notes

Flex-18 gates contain counter balancing springs that are exactly calibrated for a specific arm length. As a result, any field modification of arm length require correct recalibration of the spring tension. Consult CPEAPE factory for more information.

Barrier Gate Features

- Housing made of folded and welded 10-gauge steel sheet.

- Removable upper hood. Upper hood fixed by two latches designed to resist vandalism.

- Lateral door side mounted for easy access to mechanism.

- Extruded aluminum arm.

- Electromechanical assembly including:

- 120VAC single-phase motor.

- Lubricated speed reduction gearbox with worm screw.

- Balance achieved by built-in extension spring. No external counterweights.

- Crankshaft-rod device ensuring smooth, progressive operation.

- Mechanical locking of barrier arm in extreme positions (Closed/Open), with rubber bumpers.

- Easily reversible main shaft.

- Easily adjustable limit switches with mechanical and controller overrun protection.

- Barrier arm shaft mounted on two pillow blocks with welded arm support.

- Shaft configuration allows easy barrier model inversion from left to right.

- Built-in heater.

- Easily removable 10 or 26 IO PLC logic control to ensure automatic closing of the barrier either by detector and loop or by push button. Opening of the barrier by push button, card reader or other optional controls. The 26 IO controller provides for connection of up to three optional loop detectors.

- Barrier anchoring by means of expanding bolts or threaded rods, thus allowing easy alignment with road-way (anchoring means available as option, to be defined depending on the type of ground). Fits over existing G89E bolt patterns.

- Seam welded cabinet is constructed from 10 gauge galvanized steel with polyester powdered finish for superior corrosion resistance.

- Dimensions: Approximately 42” Height x 15” Wide x 15” Deep